-

Welcome to Tundras.com!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tundra discussion topics

- Transfer over your build thread from a different forum to this one

- Communicate privately with other Tundra owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Replacing rear wheel bearings

Discussion in '2nd Gen Tundras (2007-2013)' started by FuegoMCS, Nov 17, 2024.

Oil Filter Wrench?

Oil Filter Wrench? 2nd Gen Transmission Drain and Fill DIY How-To

2nd Gen Transmission Drain and Fill DIY How-To Land cruiser 200 series snorkel

Land cruiser 200 series snorkel TRD Pro knock off grill (on eBay)

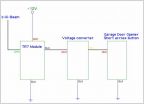

TRD Pro knock off grill (on eBay) Flash-to-Open Mod

Flash-to-Open Mod Door check replacement

Door check replacement