-

Welcome to Tundras.com!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tundra discussion topics

- Transfer over your build thread from a different forum to this one

- Communicate privately with other Tundra owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Drill bits for slider install

Discussion in 'General Tundra Discussion' started by fisherman951, Apr 11, 2019.

Page 2 of 2

Page 2 of 2

Tundra CrewMax $5 Console Mod

Tundra CrewMax $5 Console Mod What primer to treat rust on frame

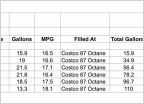

What primer to treat rust on frame Another Useless MPG Thread....

Another Useless MPG Thread.... Tide pod coolant flush

Tide pod coolant flush RAT

RAT Torque wrench preferences?

Torque wrench preferences?