-

Welcome to Tundras.com!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tundra discussion topics

- Transfer over your build thread from a different forum to this one

- Communicate privately with other Tundra owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

2002 SR5

Discussion in '1st Gen Tundras (2000-2006)' started by alockman1015, May 20, 2024.

Getting a p3400 code on my 2004 toyota tundra

Getting a p3400 code on my 2004 toyota tundra 10.1 Xtrons head unit upgrade to 12.8 Rotating unit ---AKA BIG ASS SCREENS!

10.1 Xtrons head unit upgrade to 12.8 Rotating unit ---AKA BIG ASS SCREENS! Key Fob Replacement 2002 Tundra

Key Fob Replacement 2002 Tundra 2002 Dies after it warms up. Compression codes on one side only (driver's).

2002 Dies after it warms up. Compression codes on one side only (driver's). Rear shock how-to

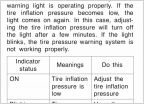

Rear shock how-to Confirmation of TPMS light status

Confirmation of TPMS light status