-

Welcome to Tundras.com!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tundra discussion topics

- Transfer over your build thread from a different forum to this one

- Communicate privately with other Tundra owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Initial Development And Prototyping Of A 102 mm GM LS Throttle Body On A Supercharged Tundra

Discussion in 'Performance and Tuning' started by ViktorG, Oct 3, 2020.

Page 14 of 15

Page 14 of 15

SABM Review

SABM Review Story of Ethanol.

Story of Ethanol. TRD Intake Flow Accelerator For Cold Air Intake. Air Intake System

TRD Intake Flow Accelerator For Cold Air Intake. Air Intake System Air Intake Tube Alternative

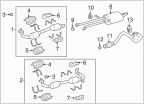

Air Intake Tube Alternative TRD Dual Exhaust swap out

TRD Dual Exhaust swap out